Need a quote? Have other questions? Talk to one of our experts.

Talk to Experts

Request Call

Get a Quote

Solutions

Digitalization

MM-IoT Hardware

MM-IoT Software

Automation

Controllers

Displays

I/O Modules

Sensors

Software Tools

Power Management

Power Distribution

Central Electrics

Battery Management

Markets

Agriculture

Construction

Electric & Hydrogen

Forestry & Harvesting

Marine

Mining

Municipal Vehicles

Railway & Transit

Contact

Product Sales

For product purchasing information

Contact Sales

Technical Support

Submit technical support requests

Contact Support

US Headquarters

STW Technic, LP.

1750 Corporate Drive, Suite 750

Norcross, GA 30093

1750 Corporate Drive, Suite 750

Norcross, GA 30093

Phone: +1-770-242-1002

STW Technic, LP © 2023

This site uses Google reCAPTCHA. View Privacy Policy and Terms of Service.

Request a Call

* Required

Digitalization

Edge Computing DevicesThe ultimate edge devices for MM-IoT applications

Device AccessoriesExplore our wide range of wireless antennas and accessories

Automation

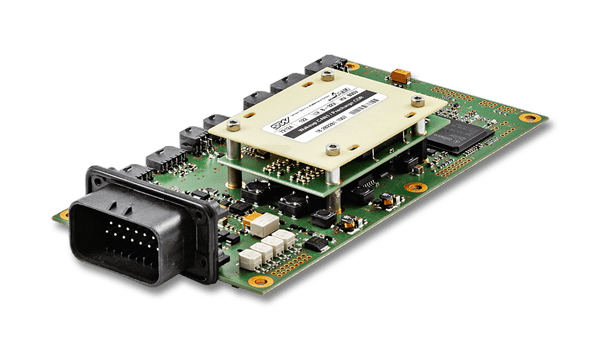

4 SeriesNext-gen mobile machine controller modules

4 SeriesNext-gen mobile machine controller modules 3 SeriesLast generation controllers with customization options

3 SeriesLast generation controllers with customization options

Display ModulesErgonomic and high visiblity displays for any application

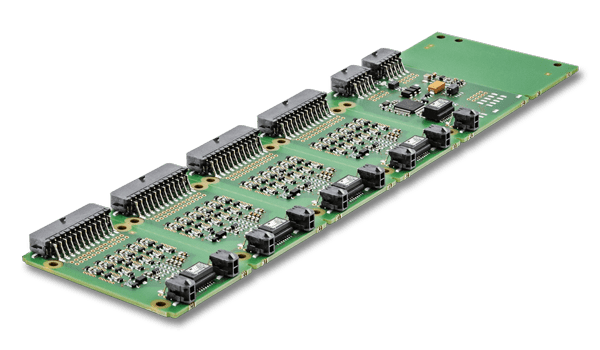

ExpansionEasy to integrate modules in multiple I/O configurations

OutputIntelligent PWM modules designed for high current applications

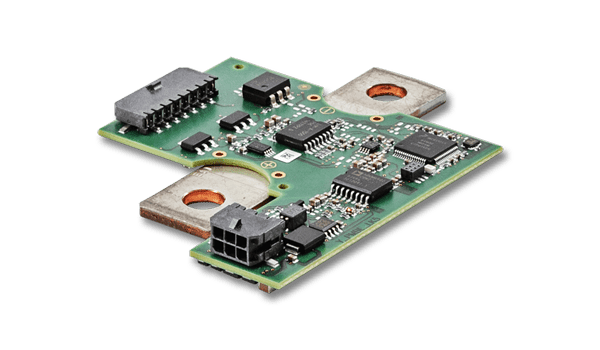

Bus SplittersEasily connect additional devices to the CAN bus

H-BridgesEfficient ways to control DC motor direction

Pressure & TemperatureRobust safety sensors with custom configuration available

InclinationReliable angle measurement in any harsh environment

EncodersAccurate rotation measurements for the toughest conditions

Development for 4 SeriesopenSYDE development with logi.CAD for our latest controllers

Development for 3 SeriesopenSYDE development with logi.CAD, CODESYS, and more

About STW Technic

Markets We Serve

AgricultureRugged technology for agriculture machinery

ConstructionPerformance for any level of mobile construction machinery

Electric & Hydrogen VehiclesPower technology for alternative fuel mobile vehicles

Digitalization

Automation

4 SeriesNext-gen mobile machine controller modules

4 SeriesNext-gen mobile machine controller modules 3 SeriesLast generation controllers with customization options

3 SeriesLast generation controllers with customization options

Display ModulesErgonomic and high visiblity displays for any application

ExpansionEasy to integrate modules in multiple I/O configurations

OutputIntelligent PWM modules designed for high current applications

Bus SplittersEasily connect additional devices to the CAN bus

H-BridgesEfficient ways to control DC motor direction

Pressure & TemperatureRobust safety sensors with custom configuration available

InclinationReliable angle measurement in any harsh environment

EncodersAccurate rotation measurements for the toughest conditions

Development for 4 SeriesopenSYDE development with logi.CAD for our latest controllers

Development for 3 SeriesopenSYDE development with logi.CAD, CODESYS, and more

About STW Technic

Markets We Serve

AgricultureRugged technology for agriculture machinery

ConstructionPerformance for any level of mobile construction machinery

Electric & Hydrogen VehiclesPower technology for alternative fuel mobile vehicles

Solutions & Products

Our Company

Contact

Contact Sales

* Required

Contact Sales

* Required

Contact Sales

* Required